5 3D Printed Tools For Woodworking

3D printed tools are quickly becoming practical additions to modern woodworking shops. Instead of buying expensive specialty jigs and guides, hobbyists can now print tools that improve accuracy, speed up repetitive tasks, and adapt to specific projects. From angle guides to drill jigs, well-designed 3D printed tools help woodworkers work smarter while keeping costs low. This article breaks down five useful 3D printed tools for woodworking and explains why they’re worth adding to your setup.

How 3D Printed Tools Can Simplify Your Woodworking Projects

3D printed tools help remove small frustrations that slow woodworking down. Instead of constantly measuring, adjusting, or repositioning, printed jigs and guides keep everything aligned from the start. This makes repeat cuts, straight holes, and consistent spacing much easier to achieve.

Because these tools can be customized, they fit your exact project needs. You can print angle guides for specific cuts, spacers for uniform gaps, or drill guides that keep bits perfectly straight. This reduces mistakes, saves material, and cuts down on wasted time.

Another advantage is accessibility. When a tool wears out or needs adjustment, you can reprint it rather than replace it. For hobbyists and DIY makers, that flexibility turns complex woodworking tasks into simpler, more repeatable processes.

What Makes a Good 3D Printed Woodworking Tool?

Not every printed tool belongs in a woodshop. Before using one, you should evaluate a few essentials.

Material choice matters. PLA works for light-duty tasks, but PETG and ABS handle heat and impact better. Nylon blends excel for drill guides and clamps.

Print orientation matters. Stress direction must align with layer strength. A poorly oriented print fails faster than a well-designed one.

Tolerance matters. Woodworking requires precision. Good tool designs include clearance allowances for sawdust, expansion, and real-world use.

When those factors align, 3D printed tools become incredibly effective.

5 Must-Have 3D Printed Tools for Woodworking

1. 3D Printed Corner Clamps

Corner clamps are one of the most popular woodworking prints—and for good reason.

They hold two boards at a perfect 90-degree angle while glue sets or screws drive in. Traditional metal clamps work, but they’re bulky and expensive. Printed versions solve both issues.

Why woodworkers love them:

- Lightweight but rigid

- Easy one-hand positioning

- Perfect for frames, boxes, and cabinets

Many designs include reinforced ribs or dual-screw channels, which significantly increase strength. When printed in PETG or nylon, these clamps hold surprisingly well.

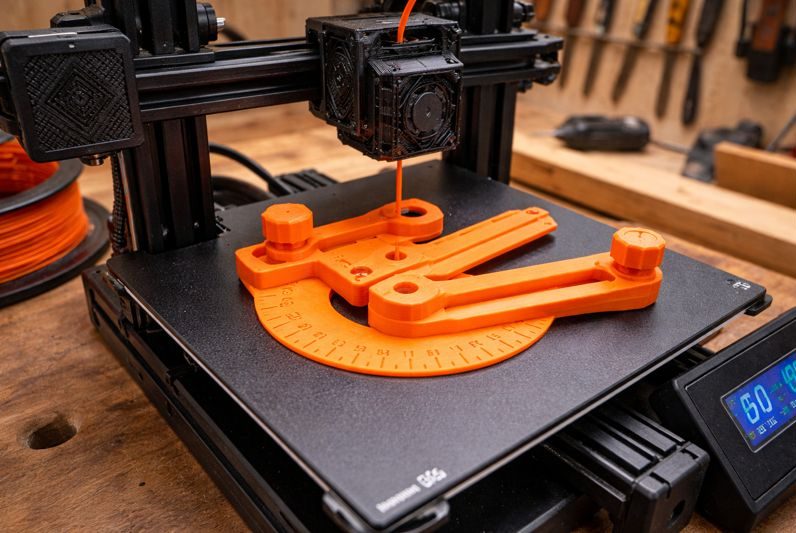

2. Precision Angle Guides

Accuracy separates clean projects from frustrating ones. A 3D printed angle guide helps you cut consistent angles without recalibrating your saw every time.

These guides clip directly onto circular saws, miter saw fences, or sanding blocks.

Key benefits:

- Fast repeatable angles

- Ideal for bevels and trim work

- Easy to modify for custom angles

Because these tools don’t carry heavy loads, printed versions perform just as well as aluminum guides in most hobby setups.

3. Adjustable Drill Guides

Freehand drilling often leads to angled holes—and wasted wood. A 3D printed drill guide keeps your bit perfectly vertical or angled at a preset degree.

Advanced designs include:

- Replaceable bushings

- Multi-angle slots

- Depth-limiting stops

Reviews consistently show improved accuracy when printed guides are used with hardwoods and softwoods alike. For shelf pins, dowels, and hardware installation, they’re invaluable.

4. Depth Stop Collars

Depth stop collars prevent drilling too deep. While metal collars exist, printed ones offer one major advantage: custom sizing.

You can print collars tailored to:

- Exact bit diameters

- Specific project depths

- Specialized drill setups

Because they’re lightweight, they don’t throw off drill balance. When printed with higher infill and tight tolerances, they hold firmly during use.

5. Custom Measuring Jigs and Spacers

This is where 3D printed tools truly shine.

Need a spacer that’s exactly 18.7 mm wide? Print it.

Need a repeatable shelf gap? Print a jig.

Need a story stick that won’t warp? Print it.

Measuring jigs reduce human error and speed up repetitive tasks. Many woodworkers now rely on printed spacers more than tape measures during assembly.

Recommended Products for DIY Woodworkers

To get the most out of 3D printed woodworking tools, pairing them with reliable gear matters. Here are five products that complement printed tools well:

- PETG Filament (High-Impact Grade) – Ideal for clamps and guides

- Carbon Fiber Reinforced PLA – Excellent stiffness for precision jigs

- Digital Caliper (0.01 mm accuracy) – Essential for design tolerances

- Compact Cordless Drill with Variable Speed – Works perfectly with printed drill guides

- Workbench Clamp Set – Supports hybrid setups with printed accessories

These products consistently receive strong reviews from both woodworkers and 3D printing hobbyists.

Why 3D Printed Woodworking Tools Can Be Surprisingly Strong

One of the biggest questions hobbyists ask is whether 3D printed tools are actually strong enough for woodworking. A comprehensive review published in the journal Materials helps answer that.

The review analyzed dozens of studies on Fused Deposition Modeling (FDM)—the same 3D printing method used to create clamps, jigs, guides, and spacers for woodworking. Researchers found that strength depends heavily on material selection and print settings, including layer orientation, infill density, and extrusion temperature.

Notably, materials such as PETG, ABS, and fiber-reinforced filaments consistently outperformed basic PLA in durability and stress resistance. When optimized, these materials were shown to handle functional, low-to-moderate load tasks reliably.

For woodworkers, this means 3D printed tools work extremely well for alignment, positioning, spacing, and guiding tasks—exactly where precision matters more than brute force.

How Accurate Are 3D Printed Jigs and Guides for Woodworking?

Precision is everything in woodworking, especially when drilling straight holes, cutting repeatable angles, or spacing shelves evenly. A recent in-depth review on dimensional accuracy in FDM 3D printing sheds light on how reliable printed jigs and guides really are.

The review explains that while FDM prints can experience minor dimensional variation, proper calibration and slicing adjustments significantly improve accuracy. Key factors include consistent nozzle temperature, calibrated extrusion flow, controlled cooling, and optimized print speed.

The findings show that when these variables are dialed in, 3D printed parts can achieve repeatable, predictable tolerances suitable for precision woodworking applications. That makes printed drill guides, angle jigs, depth stops, and spacers highly dependable for everyday shop use.

For hobbyists and makers, this research confirms that accuracy issues are not a limitation of 3D printing itself—but of setup and execution.

When 3D Printed Tools Beat Traditional Tools (and When They Don’t)

3D printed tools excel when:

- Precision matters more than brute strength

- Custom sizing is required

- Cost control is important

- Replacement speed matters

However, they shouldn’t replace:

- Load-bearing clamps

- Cutting blades

- Structural safety equipment

Smart woodworkers combine both worlds instead of choosing one.

Conclusion

3D printed tools give woodworkers more control, flexibility, and precision without added cost. When designed and printed correctly, they’re practical additions to any DIY shop. Exploring tools like a 3D printing pen for customizing and repairing prints can further expand what’s possible with 3D printed woodworking tools.

FAQs

1. Are 3D printed tools strong enough for woodworking?

Yes, for guiding and alignment tasks. PETG and nylon prints perform especially well.

2. What filament works best for 3D printed woodworking tools?

PETG is a well-rounded filament that combines toughness, slight flexibility, and easy printing performance.

3. Can I replace metal jigs with 3D printed ones?

For light-to-medium duty tasks, yes. For load-bearing jobs, metal is still better.

4. How long do 3D printed woodworking tools last?

With proper material choice and print orientation, they can last years.

5. Are 3D printed tools accurate enough for fine woodworking?

Yes. When paired with proper calibration and measurement tools, accuracy is excellent