Top 10 Must-Have 3D Printer Parts for Your Next Project

If you’ve been 3D printing for a while, you already know that the right 3D printer parts can completely transform your setup. A single upgrade can fix stubborn issues, save hours of troubleshooting, and even unlock new materials. Whether you’re using a Creality, Anycubic, Prusa, or a custom build, your hardware choices directly affect print quality, speed, and consistency.

You might be aiming for sharper details, fewer failed prints, or a quieter machine. Or maybe you’re ready to try flexible TPU, carbon fiber, or higher-temperature materials. With the right parts, you get more control, more confidence, and a smoother printing experience overall.

Now, let’s look at the 10 upgrades that make the biggest difference.

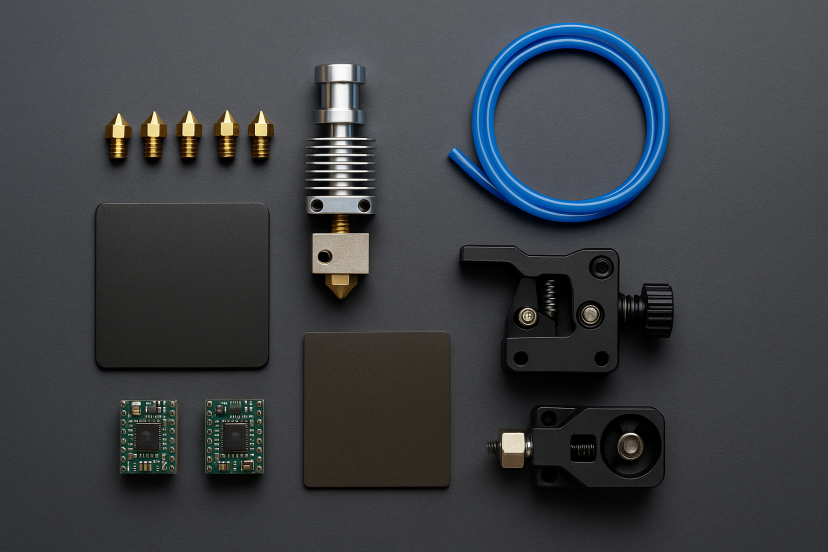

1. High-Quality Nozzles

Nozzles are small, but their impact is huge. If you’ve ever had inconsistent extrusion or fuzzy details, your nozzle might be the reason.

Why this part matters:

- Precision nozzles deliver sharper details

- Hardened nozzles handle abrasive filaments

- Better heat retention improves consistency

- They clog less often

If you print glow-in-the-dark, carbon fiber, or woodfill, upgrading to hardened steel is non-negotiable. For everyday PLA and PETG, brass is fantastic, but a well-machined nozzle always outperforms cheap stock ones.

2. All-Metal Hotend

This is one of the most valuable upgrades for serious enthusiasts.

A stock hotend typically uses PTFE inside the heat break. Over time, that tube degrades and restricts your temperature ceiling. An all-metal hotend removes that barrier.

What it improves:

- Higher maximum temperatures

- Cleaner extrusion during long prints

- Better support for Nylon, ABS, PC, and composites

- Reduced thermal creep (a common cause of clogs)

If you want to experiment with engineering materials, this is a must-have.

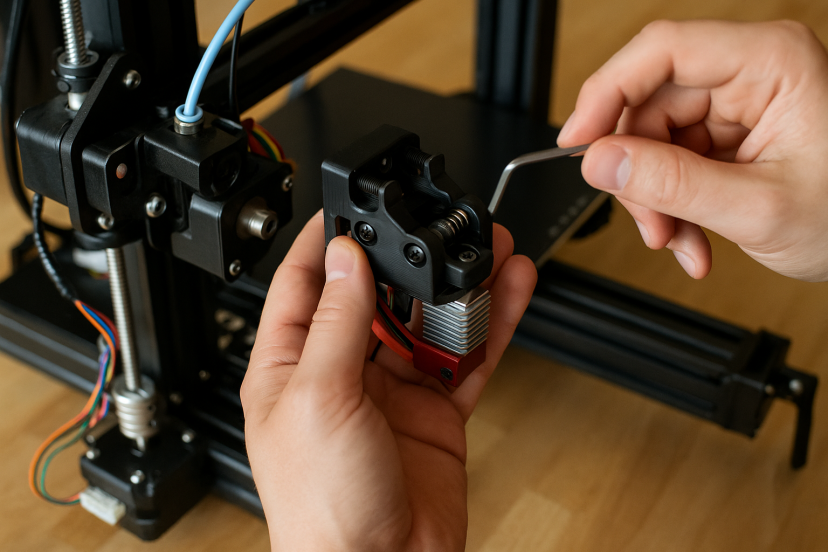

3. Upgraded Extruder Assembly

Your extruder is responsible for pushing filament consistently. When it slips, grinds, or loses grip, your print quality suffers instantly.

An upgraded extruder offers:

- Stronger, more reliable filament grip

- Cleaner retraction and fewer stringy prints

- Better support for TPU and flexible materials

- Faster, more accurate extrusion

Both direct-drive and optimized Bowden extruders benefit from dual-gear mechanisms. It’s one of the best “instant improvement” upgrades you can make.

4. PEI or Textured Build Plate

If you’re still using glue sticks, painter’s tape, or hairspray, prepare for a huge improvement.

A modern build surface like PEI, textured spring steel, or coated glass gives you:

- Strong first-layer adhesion

- Clean releases once the plate cools

- Better consistency across multiple materials

- Less time spent prepping the bed

PEI sheets in particular strike the perfect balance between grip and easy release.

5. Silent Stepper Motor Drivers

If you print at night—or even in the same room while working—the noise can become a problem. Silent stepper drivers drastically reduce the typical grinding, humming, or squealing.

They also improve print quality because:

- Smoother motion reduces vibration

- Less vibration equals cleaner outer walls

- Stepper accuracy improves dimensional consistency

This upgrade makes your printer feel far more refined.

6. Filament Dry Box

Moisture in filament is the silent enemy of print quality. It causes:

- Popping noises

- Stringing

- Weak layer adhesion

- Inconsistent extrusion

- Brittle prints

A dry box keeps your filament at a stable humidity level, which is especially important for hygroscopic materials like:

- TPU

- Nylon

- PETG

- PLA (yes, even PLA absorbs moisture)

Your layers will look instantly cleaner once you print with dry filament.

7. Dual-Gear Extruder

Dual-gear extruders grip filament from both sides. This tiny change creates major benefits, especially if you print flexible or soft materials.

Advantages include:

- Less slipping

- More predictable extrusion

- Better retraction

- Reduced stringing

- Improved detail in small prints

Flexible filaments become dramatically easier to handle.

8. Auto-Bed Leveling Sensor

Manual leveling is fine when everything goes perfectly, but even small shifts can cause major headaches. An auto-bed leveling (ABL) sensor solves this for good.

ABL sensors help you:

- Maintain a perfect first layer

- Print reliably even on slightly warped beds

- Spend less time calibrating

- Avoid adhesion-related failures

Whether you choose a BLTouch, CR-Touch, or inductive probe, the improvement is immediate.

9. Capricorn PTFE Tubing

If you’re running a Bowden setup, friction inside the PTFE tube can affect how smoothly your filament travels. Capricorn tubing is made with tighter tolerances and heat-resistant materials.

It improves:

- Extrusion smoothness

- Feeding accuracy

- Retraction response

- Compatibility at higher temps

This is a simple, inexpensive upgrade with a noticeable payoff.

10. 32-Bit Mainboard Upgrade

A 32-bit board gives your printer a faster “brain.” Older 8-bit boards struggle with high-speed movements and modern firmware features.

A 32-bit mainboard provides:

- Quieter printing (many come with silent drivers)

- Faster processing for smoother motion

- Better temperature regulation

- File handling improvements

- Access to advanced features like pressure advance

It might sound like an advanced upgrade, but installation is straightforward on most machines.

What Happens When You Upgrade Key Parts of Your Printer?

Every printer has a “baseline personality.” Some are fast but loud, while others are accurate but slow. Some are reliable but limited to basic materials. But hardware upgrades can shift those limits dramatically.

Better parts help you:

- Achieve smoother layers

- Maintain stable temperatures

- Improve bed adhesion

- Reduce vibration and ghosting

- Print more materials reliably

- Eliminate common print failures

Think of each 3D printer parts upgrade as tuning your printer like you would tune a guitar—the right adjustments create harmony. And when you stack multiple upgrades, your machine starts performing at a completely different level.

How Does Better Hardware Lead to Better Prints?

While upgrading hardware often feels like simple trial and error, there’s strong scientific research explaining why these improvements work so well.

A comprehensive review published in Polymers (2020) analyzed how temperature stability, nozzle design, and extrusion consistency affect the strength and finish of FDM-printed parts. Researchers found that printers with precise thermal control and well-designed extrusion paths produce stronger layer bonding, smoother surfaces, and more predictable mechanical properties.

This directly supports upgrades like:

- All-metal hotends

- Hardened precision nozzles

- High-flow thermal systems

When your hotend maintains stable heat and extrusion stays consistent, every layer bonds more reliably.

Another systematic review from Soft Science (2022) examined how motion accuracy, layer thickness, nozzle temperature, and print speed interact. Their major takeaway was that stable hardware dramatically improves repeatability and dimensional accuracy, especially in hobbyist printers where stock components introduce small performance inconsistencies.

This research supports real-world upgrades such as:

- Auto-bed leveling

- PEI build plates

- Dual-gear extruders

- Silent stepper drivers

- 32-bit mainboards

These components help keep your printer calibrated, steady, and consistent—even across long prints or complicated models.

Both studies reinforce the same message: better hardware leads to better prints, and upgrading key 3d printer parts isn’t just a convenience—it’s a performance boost backed by science.

Final Thoughts

Upgrading your 3D printer parts is one of the smartest ways to improve your setup. You don’t have to replace everything at once. Start with the areas that impact you the most—nozzles, hotends, and build surfaces—and expand from there as your printing skills grow.

Each upgrade sharpens the control you have over your machine. And with better control, you’ll see cleaner layers, stronger parts, and more consistent results. Whether you’re printing functional components, detailed miniatures, or seasonal gifts, these improvements help your printer work with you, not against you.

If you’re ready to elevate your prints, pick one upgrade, try it out, and enjoy the transformation. The difference speaks for itself.

FAQs

1. Do upgraded nozzles really improve print quality?

Absolutely. Precision nozzles deliver sharper details and resist clogging, especially with abrasive filaments.

2. Is an all-metal hotend necessary for PLA?

Not required, but it improves consistency and expands your material options.

3. What’s the easiest 3d printer parts upgrade for beginners?

A PEI build plate or Capricorn tubing—quick installs with big results.

4. Does filament really need to be dried?

Yes. Moist filament causes stringing, bubbling, weak layers, and unpredictable extrusion.

5. Should beginners upgrade to direct drive?

If you want to print TPU or detail-heavy models, it’s highly beneficial.