What Is SLA 3D Printing? Everything You Need to Know

You’ve spent hours designing a 3D model, carefully slicing it, and waiting for the print to finish—only to find layer lines, uneven edges, or surface imperfections. It’s discouraging, right? Many 3D printing enthusiasts hit this wall with FDM printers. The problem often lies in the printing method itself, not your skills. Enter SLA 3D printing, short for Stereolithography Apparatus. This technology uses laser-cured resin to produce stunningly smooth, high-precision prints that look like they came straight from a professional manufacturing line. If you’ve been craving cleaner details and flawless finishes, SLA might just be the upgrade your creative projects deserve.

What Is SLA 3D Printing?

SLA 3D printing, short for stereolithography, is a light-based additive manufacturing process that turns liquid resin into solid objects with incredible precision. Unlike filament printers that melt plastic, SLA uses a UV laser or projected light source to cure photosensitive resin layer by layer. According to the Ultimate Guide to Stereolithography (SLA) 3D Printing by Formlabs, this process relies on photopolymerization—a chemical reaction where light activates resin molecules, linking them together into a rigid structure.

As every layer hardens, the build platform gently rises, letting new resin spread underneath before the next layer is created. This repetitive curing and lifting motion continues until the final 3D object emerges. The result is a print with smooth surfaces, fine edges, and impressive dimensional accuracy that often requires minimal post-processing.

In modern machines, many SLA systems use what’s known as an “inverted” design, where the light source sits below a transparent resin tank. This setup reduces stress during layer separation and helps produce flawless details. As described in Wikipedia’s entry on Stereolithography, this inverted approach has become standard in desktop and professional resin printers alike, offering excellent reliability for complex geometries.

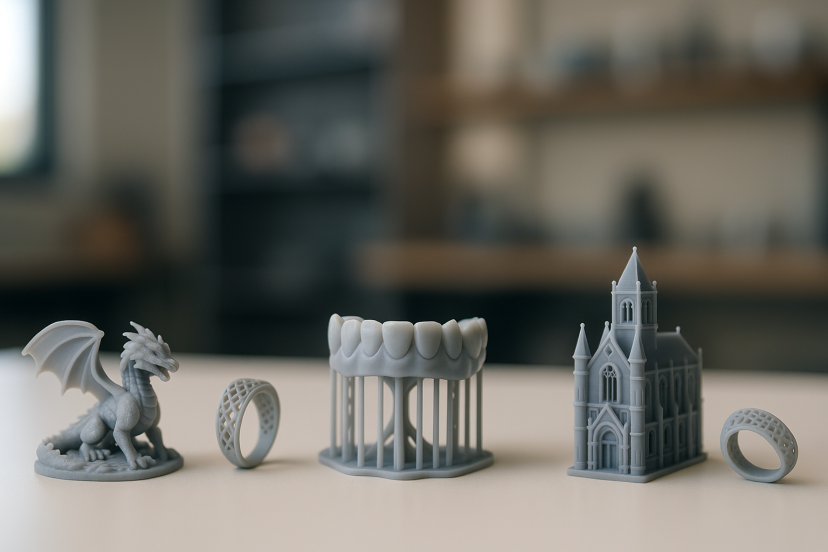

Today, SLA technology is favored for creating high-resolution prototypes, dental models, jewelry patterns, and engineering components. The combination of smooth finishes, watertight properties, and diverse resin materials—including flexible, rigid, and castable options—makes it a go-to method for precision manufacturing and design. In short, SLA transforms light and liquid into artistry and accuracy, making it one of the most versatile and refined forms of 3D printing available.

How Does SLA 3D Printing Work?

Let’s break down the SLA printing process step by step:

- Model Preparation:

You start by designing your 3D object in CAD software or downloading a model from an online repository. Then you import it into slicing software such as ChiTuBox or PreForm. - Slicing and Supports:

The software slices your model into microscopic layers and adds necessary support structures to stabilize overhangs and fine details during printing. - Laser Curing:

A precise UV laser then follows the outline of that layer, curing the resin exactly where the design requires. The resin hardens instantly wherever the light touches. - Layer-by-Layer Build:

After a layer cures, the printer’s build platform lifts slightly to allow uncured resin to flow underneath, and the next layer begins. - Post-Processing:

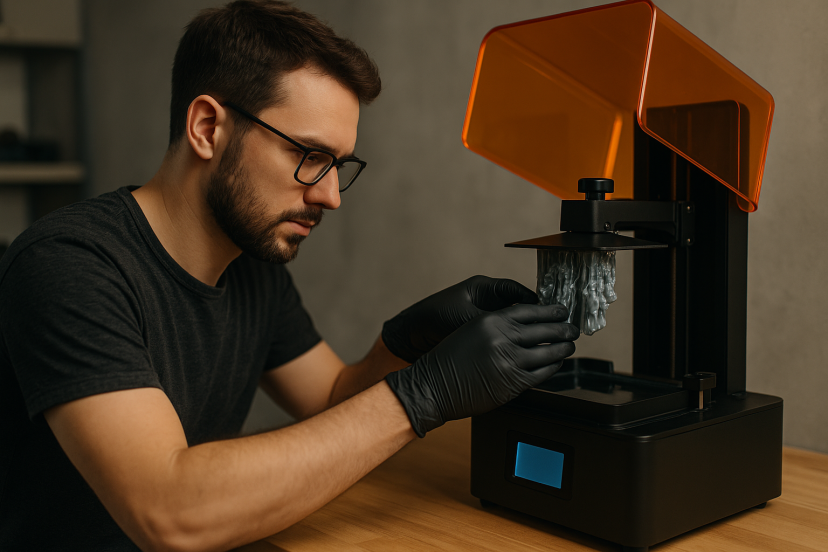

Once complete, the model is rinsed in isopropyl alcohol to remove excess resin, then cured under UV light to reach full hardness and durability.

This combination of light precision and liquid resin chemistry allows SLA to deliver results that other 3D printing methods simply can’t match.

Why Choose SLA Over FDM or SLS?

SLA is indeed a category-defining technology. Here’s why makers, engineers, and artists swear by it:

1. Ultra-Smooth Surface Finish

SLA prints require minimal post-processing. Unlike FDM prints with visible layer lines, SLA parts emerge silky-smooth, making them ideal for final presentation models or cast molds.

2. Incredible Accuracy

With precision down to ±0.05mm, SLA printers are perfect for small parts, mechanical prototypes, or components requiring tight tolerances. Jewelry designers, dental labs, and engineers all benefit from this level of consistency.

3. Versatile Resin Options

Resins come in various formulations—standard, tough, flexible, castable, and even biocompatible. That flexibility opens doors to endless possibilities, from engineering prototypes to wearable art.

4. Complex Geometries Made Easy

The laser-based curing process can handle intricate internal details and thin walls that filament printers often struggle with.

5. Professional-Grade Output at Home

Desktop SLA printers have become more affordable and user-friendly, allowing hobbyists to create industrial-quality prints without leaving their workshop.

Applications of SLA 3D Printing

SLA 3D printing isn’t just for professionals—it’s for anyone who values detail and design integrity. Here are its most common applications:

- Dental & Medical Models: Custom surgical guides, dental aligners, and anatomical replicas.

- Jewelry Design: Castable resin for precision molds and wax burnouts.

- Miniatures & Collectibles: Highly detailed figurines and prototypes for tabletop games.

- Engineering & Product Design: Functional prototypes with exact fits and mechanical precision.

- Custom Accessories: Personalized items such as 3D printed keychains or intricate decor pieces.

Top 5 SLA 3D Printers on Amazon (2025 Picks)

Ready to try SLA printing? Here are five reliable options that deliver impressive precision and smooth results.

1. Elegoo Mars 4 DLP Resin Printer

This printer combines 95% light uniformity with fast, stable performance. It delivers consistent results with minimal calibration, making it ideal for beginners and small-scale model makers.

2. Anycubic Photon Mono M7 PRO

Featuring a sharp 14K resolution and automatic leveling, the Photon Mono M7 PRO produces stunning micro-details in less time. It’s perfect for hobbyists who want precision without complexity.

3. Creality Halot-One Plus

The Halot-One Plus offers smart resin monitoring, Wi-Fi control, and a 4K mono screen. It strikes the right balance between affordability, speed, and reliability for everyday makers.

4. Phrozen Sonic Mighty 12K

With its large build volume and 12K clarity, the Sonic Mighty 8K handles multiple prints at once while maintaining detail. It’s a solid choice for small businesses and studios.

5. ELEGOO Saturn 3 Ultra

The Saturn 3 Ultra stands out with a 12K mono LCD, faster exposure times, and Wi-Fi connectivity. Its professional-grade accuracy makes it ideal for large, detailed projects.

SLA 3D Printing vs. FDM: Side-by-Side Comparison

| Feature | SLA Printing | FDM Printing |

| Surface Finish | Ultra-smooth, minimal post-processing | Visible layer lines |

| Accuracy | Extremely precise (±0.05mm) | Moderate (±0.1–0.3mm) |

| Speed | Moderate | Faster for large models |

| Material | Photopolymer resin | Thermoplastic filament |

| Ease of Use | Requires post-processing | Beginner-friendly |

| Cost | Higher resin cost | More affordable filament |

| Durability | Brittle (depending on resin) | Tougher for structural parts |

In short:

- Go with SLA for detailed, aesthetic projects.

- Choose FDM for functional or large prototypes.

Tips to Maximize SLA Print Quality

Even the best machines need a good operator. Here’s how to perfect your SLA workflow:

- Use High-Quality Resin

Cheap resin often leads to brittle or uneven prints. Stick with reputable brands for consistent curing. - Check Calibration Regularly

Level your build plate and ensure uniform laser exposure before every print. - Optimize Exposure Settings

Adjust layer exposure times to your resin type—overcuring can cause swelling, undercuring weak adhesion. - Filter Resin Between Prints

Reuse resin only after filtering out hardened debris. This prevents print defects. - Post-Cure Properly

UV curing after printing significantly improves part strength and durability. - Store Resin Safely

Keep it in opaque bottles and away from sunlight to avoid premature curing. - Ventilate Your Workspace

Always print in a well-ventilated area—resin fumes can be strong.

Follow these habits, and you’ll get consistent, professional-grade results with every print.

Environmental Impact: Is SLA Sustainable?

SLA 3D printing isn’t the greenest technology yet, as most resins are petroleum-based and require careful disposal. However, new developments are improving its footprint. As noted by UnionTech’s analysis of eco-friendly SLA materials, manufacturers are introducing plant-derived and low-VOC resins that reduce environmental impact. Combined with energy-efficient printers and recyclable packaging, these innovations are helping SLA become more sustainable over time.

Conclusion

SLA 3D printing has reshaped how makers approach precision and creativity. From detailed jewelry and dental models to custom prototypes, it consistently delivers professional-grade results that stand out for their smooth surfaces and dimensional accuracy. While it demands a bit more care and post-processing than filament printing, the quality is undeniably worth it. For anyone serious about taking their 3D printing to the next level, investing in an SLA printer is a creative transformation that elevates every project from good to exceptional.

FAQs

1. What does SLA mean in 3D printing?

SLA stands for Stereolithography Apparatus. It’s a process that uses UV light to harden liquid resin into solid 3D shapes layer by layer.

2. Is SLA printing better than FDM?

In terms of precision and finish—yes. SLA prints have smoother surfaces and finer details. FDM, however, is better for large or functional parts.

3. How long do SLA prints take?

Depending on model size and layer thickness, prints can take anywhere from 1–10 hours. The trade-off for time is incredible quality.

4. Is resin printing safe at home?

Yes, as long as you wear gloves, use ventilation, and cure prints properly. Modern resins are safer and less odorous than older formulas.

5. Can I use SLA printing for small-scale production?

Absolutely. Many small businesses use SLA for short production runs, especially for dental models, jewelry, or custom accessories.