3D Printing Innovations You Need to Know About

3D printing innovations are changing how people design, build, and create. What once required constant adjustments and technical know-how is now more accessible, reliable, and efficient. Smarter printers, improved materials, and better software have reduced failed prints and shortened the learning curve. As a result, 3D printing is no longer just an experimental hobby. It has become a practical tool for enthusiasts, designers, and small-scale makers who want consistent, real-world results.

Why 3D Printing Is Becoming Easier, Smarter, and More Reliable

3D printing used to feel complicated. Small mistakes could ruin a print, waste filament, and burn hours of time. That experience is changing fast. Today’s 3D printing feels easier because the technology is finally working with users instead of against them.

One big reason is smarter hardware and software. Modern printers can detect problems while a print is running. They pause when something goes wrong. Some even adjust settings automatically. This means fewer failed prints and less babysitting during long jobs.

Materials have also improved. Filaments are more consistent, stronger, and easier to print with than they were a few years ago. Even recycled and eco-friendly materials now deliver reliable results. That makes experimenting less risky and more rewarding.

Setup has become simpler too. Features like automatic bed leveling, better build plates, and guided calibration remove many early frustrations. There’s less trial and error, which leaves more room for actual making.

That consistency is what makes modern 3D printing more dependable. Prints finish more often. Parts fit better. Results are more predictable. Whether you’re a beginner or an experienced maker, 3D printing now feels approachable instead of intimidating.

That shift is why so many people are sticking with the hobby—and why professionals are trusting it for real-world use.

Smarter Materials Are Changing What’s Possible

Self-Healing and Smart Filaments

One of the most exciting 3D printing innovations is material intelligence. Researchers are creating filaments that react to heat, stress, or damage. This idea is not just theoretical. A major review published in Polymer Degradation and Stability explains how a material handles heat and bonds between layers directly affects strength and durability. That is why newer polymers are being designed to behave more predictably instead of cracking or warping.

Some experimental filaments can partially self-heal when heated. Others become more flexible as temperatures change. These materials are still developing, but the research shows clear progress. For enthusiasts, this means stronger parts and fewer failed prints.

Sustainable and Recycled Materials

Sustainability is now a real driver of 3D printing innovation. Recycled PETG, biodegradable PLA blends, and plant-based filaments are easier to find than ever. Their quality has also improved.

A large research review on additive manufacturing and process control shows that better material formulas and tighter printing control can deliver consistent results, even with recycled materials. These filaments do more than reduce waste. They often print more smoothly and predictably. That makes them better for both the environment and everyday printing.

AI and Automation in Modern 3D Printing

Error Detection and Print Optimization

Artificial intelligence has quietly entered the 3D printing workflow. Many modern printers now use cameras and sensors to monitor prints in real time.

Instead of discovering a failure hours later, AI systems pause prints automatically when issues appear. Some even adjust extrusion or speed mid-print to prevent defects.

That single innovation saves time, filament, and frustration.

Predictive Maintenance

Another underrated innovation is predictive maintenance. Printers can now track usage patterns and warn you before parts fail.

For enthusiasts running frequent prints, this reduces downtime and keeps projects moving without surprises.

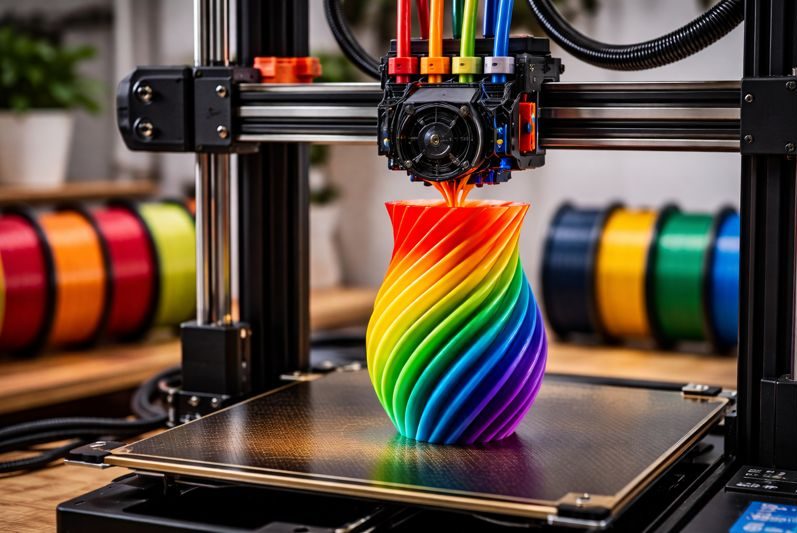

Multi-Material and Multi-Color Printing Breakthroughs

Multi-material printing used to be complex and expensive. Now, it’s becoming mainstream.

New extruder designs allow seamless switching between materials during a single print. That means flexible hinges combined with rigid frames or color-coded functional parts straight off the build plate.

This innovation removes assembly steps and opens creative doors for functional design.

Speed Innovations: Faster Prints Without Sacrificing Quality

Speed used to mean sacrificing detail. That trade-off is disappearing.

CoreXY motion systems, vibration compensation, and smarter slicing algorithms allow printers to move faster while maintaining accuracy.

For enthusiasts, faster printing means more iteration, more experimentation, and faster learning—without compromising results.

Recommended Products

Here are five highly rated tools that align with current 3D printing innovations and support better results:

- Digital Caliper (High-Precision, Stainless Steel) – Essential for dimensional accuracy and repeatable designs.

- All-Metal Hotend Upgrade Kit – Supports high-temperature materials and improves extrusion stability.

- PEI Magnetic Build Plate System – Reduces print failures and simplifies part removal.

- Enclosed Filament Dry Box – Protects filament quality and improves surface finish consistency.

- Automatic Bed Leveling Sensor – Removes one of the biggest barriers for beginners and pros alike.

These tools don’t just improve prints—they remove friction from the entire process.

Where 3D Printing Innovations Are Headed Next

Looking ahead, expect tighter integration between design software, printers, and materials. Cloud-based slicing, real-time collaboration, and adaptive material profiles are already emerging.

For enthusiasts, the future means spending less time troubleshooting and more time creating.

As 3D printing becomes more reliable, many makers also turn to practical 3D printed tools to improve setup, organization, and day-to-day printing efficiency.

Conclusion

3D printing innovations have reshaped the entire experience, from setup to final results. Smarter printers reduce errors, advanced materials improve durability, and modern tools make the process easier to manage. These changes allow enthusiasts to focus on creativity instead of troubleshooting. As the technology continues to mature, 3D printing is becoming a dependable way to build functional parts, explore new ideas, and turn concepts into finished objects with confidence.

FAQs

1. What are the most important 3D printing innovations today?

AI monitoring, advanced materials, and multi-material printing lead the list.

2. Are these innovations beginner-friendly?

Yes. Many innovations actually reduce the learning curve.

3. Do faster printers reduce print quality?

Modern systems maintain accuracy through vibration control and smarter motion planning.

4. Is sustainable filament worth using?

Absolutely. Many recycled filaments now match or exceed traditional PLA performance.

5. How can enthusiasts keep up with new innovations?

Follow research publications, maker communities, and regularly update firmware and tools.