Carbon Fiber 3D Printer: High-Performance Printing

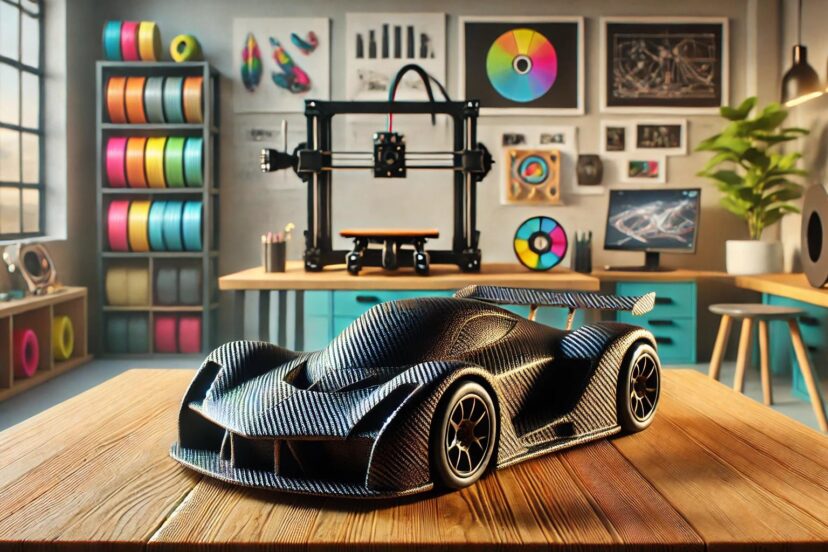

Do you often struggle to bridge the gap between your 3D printer and your project’s requirements? Creating lightweight yet durable parts can be a challenge, especially for materials like PLA and ABS. But hear me out: a carbon 3d printer lets you print incredibly strong, lightweight, and heat-resistant parts using carbon fiber. Ready to create a strong print with a nice matte finish? Continue reading below to learn more.

What is a Carbon Fiber 3D Printer?

Picture a tool so precise and capable that it feels like it has its own personality. A carbon fiber 3D printer is not your average gadget—it’s a powerhouse that combines the creative possibilities of 3D printing with the sheer strength of carbon fiber. This isn’t just a step up from conventional printing; it’s a leap. These printers create parts that are feather-light yet unyieldingly strong, ideal for everything from industrial prototypes to hobbyist projects. They don’t just print objects; they craft possibilities.

Carbon Fiber: Why Use It for 3D Printing?

Imagine crafting something as light as a dandelion seed yet as strong as steel beams. Carbon fiber brings that dream to life. It’s the perfect material for anyone who needs strength without bulk. Whether you’re designing a drone that soars like a bird or crafting a bike frame that defies gravity, carbon fiber offers a balance of elegance and resilience. And its heat and wear resistance? That’s just icing on the cake for those tackling tough environments.

How Is 3d Printing Carbon Fiber Done?

If traditional 3D printing is painting, carbon fiber 3D printing is sculpting. The process involves intertwining thermoplastic material with carbon fibers, creating a marriage of flexibility and strength. These fibers, like tiny threads of potential, either scatter throughout the filament in chopped pieces or run continuously for maximum durability. As the printer extrudes layer by meticulous layer, the material hardens into something extraordinary. It’s like watching a master artist at work—except the canvas is a spool of filament, and the masterpiece is pure innovation.

Short Fiber vs. Continuous Fiber: What’s the Difference?

Think of short fibers as confetti—tiny fragments that spread throughout the material, adding strength without complicating the printing process. Continuous fibers, on the other hand, are the marathon runners of this world, offering unbroken reinforcement that transforms ordinary prints into engineering marvels. If short fibers are versatile and friendly, continuous fibers are the serious professionals, stepping in when performance is non-negotiable. Choosing between the two depends on your ambition and the story you want your project to tell.

Applications: Where Do Carbon Fiber Prints Shine?

From the skies to the roads, carbon fiber prints are rewriting the rules. In aerospace, they’re the quiet heroes behind lightweight drones and sturdy aircraft components. In the automotive world, they give custom car parts their flair and strength. Sports equipment, too, has been revolutionized—think bikes that glide effortlessly or tennis rackets that pack a punch. Even prototyping has evolved, as engineers can now test functional parts that mirror their final designs. Wherever innovation is needed, carbon fiber steps up like a trusted ally.

Must-Have Products for Carbon Fiber 3D Printing

Here are some must-have products to get the most out of your carbon fiber 3D printing experience:

- Creality Ender 5 S1

- A reliable, budget-friendly option with excellent support for carbon fiber filaments. Equipped with a durable nozzle for abrasive materials.

- Prusa i3 MK3S+

- Known for its precision and compatibility with a wide range of filaments, including carbon fiber. Ideal for hobbyists and professionals alike.

- eSUN Carbon Fiber PLA Filament

- A beginner-friendly filament offering a balance of strength and ease of use.

- PolyMaker PolyMide CoPA

- A durable, heat-resistant nylon-carbon fiber blend perfect for functional parts.

- Hardened Steel Nozzles

- Look for brands like Micro Swiss or E3D for replacement nozzles that can handle carbon fiber’s abrasiveness.

These products ensure smooth printing, superior results, and an optimal experience with your carbon fiber 3D printer.

Benefits of Using a Carbon Fiber 3D Printer

Let’s talk about the real perks of this technology. First, the strength-to-weight ratio is unparalleled—it’s like having a feather that could carry a brick. Then there’s the durability; these prints can weather the toughest conditions without breaking a sweat. Add precision to the mix, and you’ve got the ability to create intricate designs that are as practical as they are beautiful. It’s not just a tool; it’s a ticket to possibilities you didn’t know existed. Want to protect your 3D printer? Check out this article on 3D printer enclosure.

Key Insights from Carbon Fiber 3D Printing Research

Recent reviews highlight the advancements and applications of carbon fiber 3D printing. A systematic review titled “3D-Printed Carbon Fiber Reinforced Polymer Composites” delves into how printing parameters like infill density and layer thickness impact the mechanical properties of printed parts. Additionally, the study “Carbon Fiber 3D Printing: Technologies and Performance” evaluates the strengths of short and continuous fiber printing methods, emphasizing their roles in achieving superior strength and stiffness in printed materials. These findings underscore the versatility and transformative potential of carbon fiber in 3D printing technology.

Limitations to Keep in Mind

But like every superhero, carbon fiber 3D printing has its kryptonite. It’s not the cheapest option out there, and its abrasive nature can wear down printer parts quicker than you’d expect. Think of it as driving a sports car—you’ll need premium fuel and regular maintenance. Prints can also be less flexible, making them less suitable for projects requiring elasticity. However, with a little foresight and care, these hurdles become mere stepping stones.

Can Any 3D Printer Handle Carbon Fiber?

Not all 3D printers are created equal, and carbon fiber demands more from its machine. Ordinary brass nozzles? They’ll crumble under the pressure. You need a printer equipped with hardened steel or ruby nozzles, built to withstand the filament’s abrasive nature. And let’s not forget temperature control; some carbon fiber filaments need a heat setting that could rival a midsummer desert. The right printer isn’t just a luxury—it’s a necessity.

Popular Brands for Carbon Fiber Filaments

When it comes to choosing a filament brand, quality matters. Hatchbox offers reliable options for beginners, while Proto-pasta caters to those craving premium results. eSUN strikes a balance, providing a wide range of filaments suitable for both novices and experts. Exploring different brands is like sampling fine wines—each has its unique flavor, and finding your favorite is part of the adventure.

Environmental Impact: Is It Sustainable?

Carbon fiber 3D printing walks a fine line between innovation and environmental responsibility. While the materials themselves aren’t biodegradable, the process reduces waste compared to traditional manufacturing. Lightweight components can also improve energy efficiency in applications like vehicles. As recycling and sustainability efforts evolve, carbon fiber printing may strike an even better balance between performance and the planet.

Conclusion

Carbon fiber 3D printing isn’t just a technology; it’s a testament to human ingenuity. From aerospace marvels to everyday prototypes, its applications stretch as far as your imagination can reach. Yes, it demands investment and care, but what you gain is the ability to craft parts that are nothing short of extraordinary. Whether you’re a curious hobbyist or an industry innovator, now is the time to embrace this cutting-edge technology and let your creativity soar. So why not take the leap? The possibilities are endless, and the future is light, strong, and beautifully printed.

5 FAQs About Carbon Fiber 3D Printers

- Is carbon fiber 3D printing expensive?

It can be, but entry-level options make it accessible to hobbyists as well. - Are carbon fiber filaments compatible with standard 3D printers?

Only if your printer is equipped with a hardened nozzle and can handle higher temperatures. - Are carbon fiber prints heat-resistant?

Yes, but the level of heat resistance depends on the base material used. - Do carbon fiber filaments require special storage?

Absolutely. Keep them in a dry, airtight container to prevent moisture absorption. - What are the common issues with carbon fiber 3D printing?

Nozzle wear, filament moisture, and slower print speeds are typical challenges, but they’re manageable with proper care.