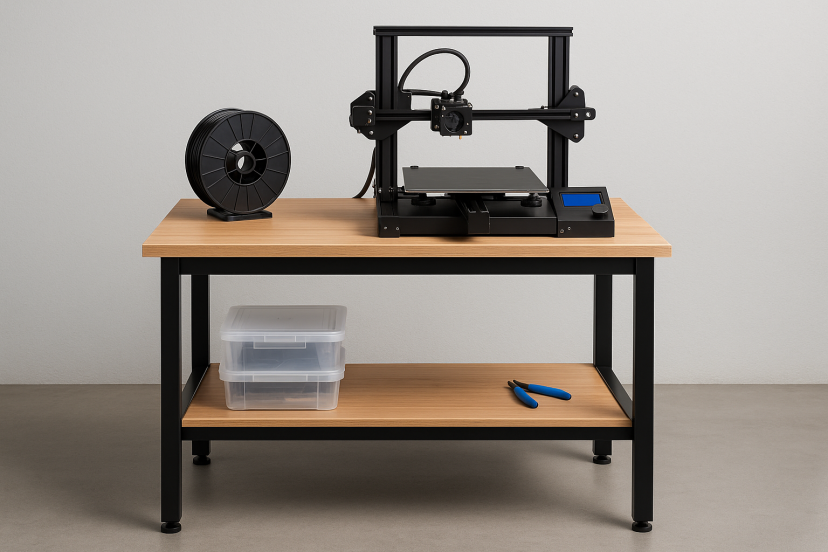

3D Printer Table Ideas for Stable, Organized Printing

A 3D printer in action is anything but still—it shakes, heats up, and demands pinpoint accuracy. The problem? Setting it on a wobbly desk or makeshift surface can lead to poor print quality, frustrating layer shifts, and even machine wear over time. These small oversights can derail entire projects, especially when printing large or intricate models. That’s why investing in the right 3D printer table is essential. In this guide, we’ll break down exactly what to look for, explore the best ready-made and DIY options, and help you create a workspace that’s stable, organized, and built for success.

Why a Dedicated 3D Printer Table Matters

It might sound like overkill to buy a special table just for your 3D printer. But once you start using it regularly—or printing large, multi-hour projects—you’ll understand why it’s essential.

Here’s what a proper table does for you:

- Reduces vibration, which leads to cleaner prints

- Protects your floors and workspace from heat, resin, or debris

- Organizes tools, filaments, and accessories

- Improves airflow for better machine health and cooling

- Minimizes noise and structural stress on your machine

And let’s be honest—having a dedicated printing station just feels awesome. It tells everyone: this is my creative zone.

Key Features to Look for in a 3D Printer Table

Whether you’re shopping or building, make sure your table includes the following must-haves:

1. Rock-Solid Stability

Wobbles equal warped layers. Look for sturdy construction—metal frames, thick tops, and leveling feet. Wood is okay, but steel is better for heavier printers.

2. Proper Ventilation

Your printer generates heat and sometimes emits fumes. Choose open-frame designs or add cutouts for airflow if you enclose the table.

3. Built-in Storage

Drawers, shelves, and hooks keep your tools, nozzles, and filament handy. You’ll thank yourself mid-project when you don’t have to go hunting.

4. The Right Dimensions

Measure your printer’s footprint, then add a few inches for cables, maintenance, and potential enclosure upgrades.

5. Optional Mobility

Lockable wheels are great if you need to move your printer for maintenance or to share space.

Top 5 3D Printer Tables

Here are the most popular, hobbyist-approved tables for your 3D printer:

1. Seville Classics UltraHD Workbench

- Heavy-duty steel frame and solid wood top

- Adjustable height and leveling feet

- Great for FDM printers and resin machines

2. IKEA LACK Table Hack

- Affordable and beginner-friendly

- Customizable for enclosures or stackable mods

- Perfect for Ender 3, Mini printers

3. FEZIBO Electric Height Adjustable Standing Desk

- Converts between sitting and standing modes

- Cable management tray included

- Doubles as a hybrid workspace

4. 2x4basics Custom Workbench Kit

- DIY flexibility: add your own lumber

- Includes heavy-duty brackets and plans

- Customize to any dimension or tier

5. Stainless Steel Table

- Rust-resistant, easy-to-clean surface

- Great for resin printers with potential spills

- Includes shelf and wheels for mobility

Why Stability and Vibration Matter

Recent research highlights just how crucial a stable 3D printer table is to print success. A study published by Springer on the effects of base vibration on 3D print quality found that even slight vertical movements significantly reduce surface smoothness and dimensional accuracy, underscoring the need for vibration-dampening setups.

Similarly, a 2021 paper from MDPI on vibration-assisted fused deposition modeling demonstrated that controlled vibration—not unwanted table wobble—can actually improve inter-layer adhesion and reduce porosity, reinforcing the value of isolating external movement while printing. These findings confirm that your 3D printer table plays a direct role in determining the final print quality.

If you’re dealing with poor layer adhesion, warping, or print artifacts, it’s worth exploring whether table stability is the culprit. You can also check out this detailed guide on common 3D printing fails and how to fix them to troubleshoot specific issues and improve your setup even further.

Setting Up Your 3D Printer Table the Right Way

Buying the table is just the first step. To turn it into a proper print station:

Use Anti-Vibration Pads

Install rubber feet or silicone pads under your printer. They reduce noise and print distortion.

Cable Management

Velcro straps, clips, or a cable raceway will prevent wires from snagging or pulling during print head movement.

Add a Filament Holder

Mount one above or beside the table. It ensures smooth filament flow and prevents tangles.

LED Strip Lighting

Install under-shelf or edge-mounted lights to clearly see nozzle action, layer quality, or messes.

Fire Safety

A fire extinguisher should be close at hand. It’s rare, but power surges or damaged heaters can start fires.

DIY Ideas: Build Your Own 3D Printer Table

If you’re handy, building your own table gives you full control. Here’s a simple breakdown:

Tools You’ll Need:

- Power drill

- Saw (if cutting lumber)

- Leveler

- Screws, brackets, and clamps

Basic Build Design:

- Use 2×4 lumber for legs and frame

- Top with thick plywood or MDF board

- Add a second shelf beneath for filament bins or a tool caddy

- Optional: install caster wheels or mount pegboards to the side

Total cost? Often under $100. And you’ll have something custom that fits your exact space.

Fun Add-ons to Personalize Your Space

Your 3D printer table can be as basic or personalized as you like. Here are some fun extras:

- Paint or stain the table to match your room

- Use magnetic tool holders for spatulas, calipers, or glue sticks

- Add a USB-powered fan to cool your stepper motors

- Install a small mirror to inspect the first layer from below

And for enclosure fans: add clear acrylic panels around the tabletop, a temperature sensor, and a vent fan for perfect print conditions.

Conclusion

Your 3D printer is capable of amazing things—but it can’t do much on a shaky or cluttered surface. Investing in a proper 3D printer table isn’t just about aesthetics. It’s about getting cleaner prints, safer operation, and more enjoyable sessions in your maker zone. Whether you buy a heavy-duty bench, repurpose a table, or build your own masterpiece, one thing’s clear: your printer deserves a home that matches your creative ambition.

FAQs

1. How big should a 3D printer table be?

Most standard printers fit on 24” x 30” surfaces. Measure your printer’s base plus 4–6 inches on each side.

2. Can I use a regular table for resin printing?

Technically, yes—but choose one with a wipeable surface, like stainless steel or sealed wood, to handle resin spills.

3. How much weight should a 3D printer table hold?

Aim for 75–150 lbs. Printers, tools, and enclosures add up fast—especially with metal-frame units.

4. Should I enclose my table for ABS or PETG prints?

Yes! Enclosures help maintain stable temperatures and reduce warping. Just ensure you add ventilation.

5. Where should I place my 3D printer table?

Avoid drafty spots or direct sunlight. Ideal locations are dry, level, and well-ventilated—like a basement, workshop, or spare room.