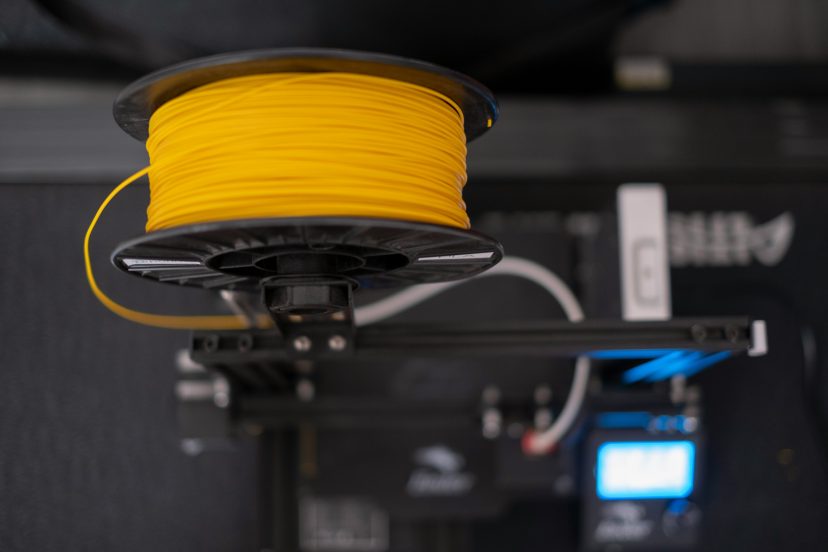

3D Printing Materials That Deliver Professional-Grade Results

Choosing the right 3D printing materials can feel overwhelming, especially when you see the long list of options. PLA, ABS, PETG, resins, carbon fiber, and even metals are all on the table. At first it feels exciting, but the challenge comes quickly. Pick the wrong one and your print might warp, crack, or fail halfway through.

Watching hours of work go to waste is discouraging, but it doesn’t have to be that way. With a clear understanding of what each material can do, you can choose the right one for the job. That choice is what leads to professional-grade results, whether you’re creating a simple prototype, a working part, or a highly detailed model.

Why 3D Printing Materials Matter

Think of materials to be 3D printing’s DNA. Your filament or resin determines how your print turns out, much like the type of wood influences how sturdy furniture is or how fabric alters how clothes feel.

- Want durability? Materials like ABS and polycarbonate excel.

- Need flexibility? Nylon and PETG are your go-to choices.

- Looking for sustainability? PLA offers a biodegradable option.

According to a 2023 Additive Manufacturing study, using the proper material enhances structural strength by up to 35% and dramatically lowers print failure rates. In other words, material selection is not discretionary; it is necessary.

Common Types of 3D Printing Materials

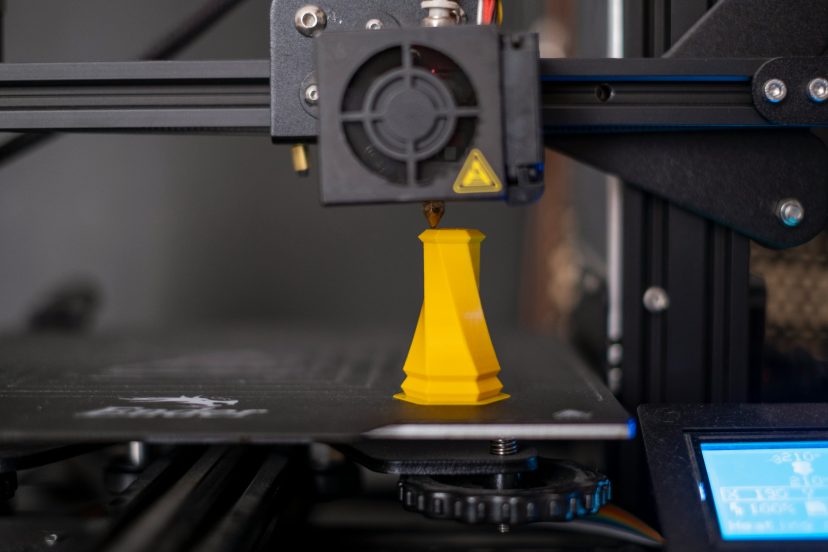

1. PLA (Polylactic Acid)

PLA is often the first stop for beginners. Made from renewable resources like corn starch, it’s biodegradable and prints at relatively low temperatures.

- Pros: Affordable, low warping, great for decorative prints.

- Cons: Brittle and not ideal for high-stress applications.

- Best for: Prototypes, figurines, hobby projects.

2. ABS (Acrylonitrile Butadiene Styrene)

A step up in strength, ABS is widely used in consumer goods and toys (think LEGO bricks).

- Pros: Strong, impact-resistant, and durable.

- Cons: Emits fumes when printing and requires a heated bed.

- Best for: Functional parts, tool handles, enclosures.

3. PETG (Polyethylene Terephthalate Glycol)

PETG blends the user-friendliness of PLA with the durability of ABS. It’s becoming a favorite for enthusiasts who want “the best of both worlds.”

- Pros: Strong, flexible, minimal warping.

- Cons: Slightly more challenging to fine-tune compared to PLA.

- Best for: Consumer products, mechanical parts.

4. Nylon (Polyamide)

Nylon is both tough and flexible, making it suitable for demanding applications.

- Pros: Abrasion-resistant, semi-flexible, and strong.

- Cons: Absorbs moisture easily, requiring dry storage.

- Best for: Wearable parts, hinges, and mechanical prototypes.

5. Polycarbonate (PC)

Known as one of the toughest consumer filaments, polycarbonate is used in engineering applications.

- Pros: Extremely strong and heat-resistant.

- Cons: Difficult to print without an enclosed chamber.

- Best for: Industrial and automotive parts.

Beyond Filaments: Resins and Advanced Materials

While filaments dominate hobbyist printing, resin-based materials are just as powerful.

Resins (SLA/DLP Printing)

- Epoxy Resin: Offers high detail and smooth surfaces.

- Pros: Perfect for jewelry, dental applications, and miniatures.

- Cons: Brittle and requires post-curing with UV light.

Metals

Stainless steel, titanium, and aluminum powders make it possible to 3D print aerospace components and medical implants. These are usually reserved for industrial machines.

Carbon Fiber Composites

Carbon fiber can be added to PLA, nylon, or PETG filaments. The result is a stiffer, lighter material that rivals aluminum in some applications.

Specialty Blends

- Wood-Filled Filaments: PLA infused with wood particles, giving your prints a natural look.

- Wax: Used for creating molds in investment casting.

How to Choose the Right Material for Your Project

Ask yourself:

- What’s the end-use? Decorative piece, wearable part, functional prototype?

- Can your printer handle it? (e.g., enclosed chamber for PC or heated bed for ABS)

- Budget concerns: PLA and PETG are affordable; specialty filaments cost more.

- Sustainability preferences: PLA and recycled filaments are eco-friendlier.

For more on turning projects into cozy creations, check out cozy autumn decor ideas, especially if you’re crafting custom fall-themed 3D decor!

Top 5 Recommended Products

Here are five Amazon picks that consistently deliver reliable performance:

- HATCHBOX PLA Filament

Affordable and dependable, this PLA is easy to print and perfect for prototypes. - Overture PETG Filament

Known for excellent layer adhesion, it’s ideal for prints requiring strength and flexibility. - Polymaker Polycarbonate Filament

Offers industrial-level durability for demanding projects. - Siraya Tech Fast Resin

A high-resolution resin for SLA/DLP printers that balances speed and detail. - Polymaker Fiberon Carbon Fiber Nylon

Extremely strong yet lightweight—perfect for advanced makers.

Comparing Strength, Durability, and Cost

| Material | Strength | Flexibility | Cost | Best Use Case |

| PLA | Low-Med | Low | $ | Prototypes, decorative objects |

| ABS | High | Med | $$ | Functional parts, toys |

| PETG | High | Med-High | $$ | Durable consumer goods |

| Nylon | Very High | High | $$$ | Mechanical, wearable parts |

| Polycarbonate | Very High | Med | $$$$ | Industrial components |

| Resin | Med-High | Low | $$ | High-detail models, dental molds |

Scientific Insights and Community Reviews

A 2022 study in the Journal of Process Manufacturing found that carbon-fiber reinforced PLA improves tensile strength, making it a stronger alternative to standard PLA.

Another peer-reviewed paper in Polymers showed that continuous carbon-fiber composites boost tensile strength by up to 400% compared to pure PLA, highlighting the huge potential of fiber reinforcement in additive manufacturing.

From the community side, makers consistently point out that PETG is the sweet spot between ease of use and durability, making it one of the most reliable filaments for everyday prints.

Resin users also emphasize its unmatched precision for detailed models and dental applications, making it the go-to material for high-resolution work.

This blend of scientific research and real-world user experience ensures hobbyists can make smarter, more confident material choices.

Practical Tips for Printing with Different Materials

- Store filaments properly. Nylon and PETG absorb moisture quickly—use airtight containers.

- Use a heated bed for ABS. This minimizes warping and improves adhesion.

- Print PLA cooler. Lower temperatures prevent stringing and improve surface finish.

- Handle resins carefully. Always wear gloves and cure them under UV light after printing.

- Experiment slowly. Start small when testing new materials to avoid wasting filament.

Conclusion

The variety of 3D printing materials today means you’re no longer limited to just one or two choices. From beginner-friendly PLA to industrial-strength polycarbonate and carbon-fiber composites, the material you choose defines the outcome of your print. Whether you’re chasing durability, precision, or eco-friendliness, the right material ensures your projects look professional and perform as intended.

Instead of guessing, invest in materials that align with your project goals—and you’ll spend more time enjoying your creations and less time fixing failed prints.

FAQs

1. What’s the most durable 3D printing material?

Polycarbonate and carbon-fiber composites are among the strongest consumer options.

2. Which filament works best for someone new to 3D printing?

PLA is perfect for beginners thanks to its low warping, affordability, and ease of use.

3. Can I print metal parts at home?

Not typically. Metal requires industrial printers, but metal-infused filaments are available for hobbyists.

4. How does resin printing compare to filament printing?

Resin printing excels in detail and finish, while filament is more versatile and cost-effective.

5. Are there sustainable or eco-friendly options for 3D printing?

Yes, PLA is biodegradable, and several companies now produce recycled filaments.