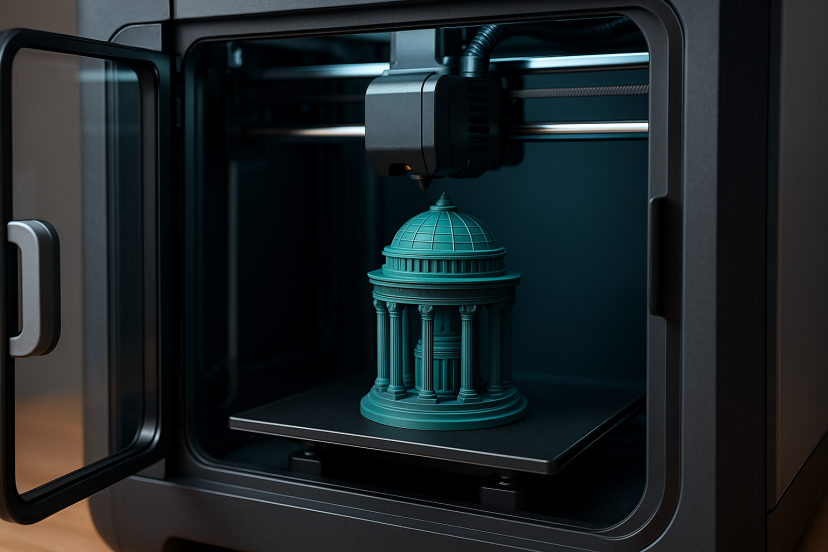

Top 10 Enclosed 3D Printers for Safer and Smarter Printing

If you’ve ever struggled with uneven prints, warping corners or worrying about fumes in your workshop, you’re not alone. Many hobbyists find that open-frame machines simply don’t cut it when things heat up—literally. That’s where an enclosed 3D printer comes in: it locks in temperature, tames emissions and delivers more consistent results. In this article I’ll walk you through why choosing an enclosed unit matters, show you ten of the best models, and share tips so you get the most from your purchase.

Why Choose an Enclosed 3D Printer Over an Open-Frame Model

Enclosed machines provide real advantages for enthusiasts and professionals alike. First, they help maintain a stable internal environment—heat, drafts and humidity are all better controlled. Second, they improve safety: high-temperature beds, hot nozzles and moving mechanisms are covered, which reduces risk of accidental contact. Third, they address air-quality and fume issues—especially when printing ABS, nylon or other high-temp filaments that can emit volatile organic compounds.

If you’ve been frustrated by prints lifting at the corners, inefficient layer adhesion or simply dealing with “messy” printing sessions, choosing an enclosed machine offers a solution—and one you’ll be grateful for.

Key Benefits of Using an Enclosed 3D Printer

Improved Print Quality

With an enclosure your build chamber retains heat and shields your print from drafts. That leads to better adhesion of layers and fewer warps. Reports show that consistent temperature control is a major factor in producing reliable prints.

Enhanced Safety and Cleaner Environment

Enclosures provide a physical barrier between you and hot components. They often include filtration or at least containment of fumes and ultrafine particles, reducing exposure to harmful emissions.

Better Material Compatibility

If you want to try ABS, PETG, nylon or carbon-fiber-infused filaments, an enclosed chamber helps these materials perform properly. The controlled environment reduces temperature shocks and helps layers stick.

Quieter, More Controlled Printing

By virtue of the casing, noise and dust are better contained. And if your workspace shares with others—kids, pets, co-workers—this count matters.

Integration with Creative Projects

For example, if you’re printing ambient lighting housings or decorative parts like 3D printed lamps, an enclosed printer gives you the confidence that the finish will be smooth, the fit accurate, and the filament choices broader.

Top 10 Enclosed 3D Printers for Every Budget

Here are ten well-reviewed enclosed units spanning beginner to expert budgets. Each printer comes pre-assembled and ready for instant setup.

Value Tier (Beginner-Friendly)

1. FLASHFORGE Adventurer Pro (220×220×220 mm)

A solid all-rounder with good print volume, strong reliability, and easy-to-use software. Great for first-time buyers who still want a professional finish.

2. ELEGOO Centauri Carbon Calibration (256×256×256 mm)

Fast, quiet, and impressively stable. Its 500 mm/s top speed and 20,000 mm/s² acceleration make it ideal for experimenting with different filaments.

3. FLASHFORGE Adventurer 5M Detachable (220×220×220 mm)

Compact, enclosed, and beginner-friendly. Delivers high-speed prints with consistent quality and minimal noise.

Mid Tier (More Features, Larger Volume)

4. Bambu Lab P1S Enclosed Materials Printing Precision

An entry-friendly enclosed printer optimized for everyday use. Handles ABS and PETG with ease while keeping fumes contained.

5. FLASHFORGE Easy-Maintenance Quick-Swap (220×220×220 mm)

Built for convenience with quick-swap nozzles and an enclosed chamber that maintains steady print temperatures.

6. FLASHFORGE Precision Full-Auto Calibration

Offers automatic levelling and stable construction, reducing setup time while boosting reliability for mid-to-advanced users.

7. Bambu Lab P1S Combo Materials Printing Precision

A versatile version of the P1S built for multi-material printing. Perfect for users exploring carbon-fiber or temperature-sensitive filaments.

Premium Tier (Large Volume / Advanced Materials)

8. QIDI Technology All-Around High-Speed (12.8″×12.8″×12.4″)

A high-speed enclosed printer engineered for precision and endurance. Its large chamber supports bigger builds without warping.

9. Creality K1C High-Speed Clog-Free Filaments

Known for consistent results and strong enclosure integrity. Handles engineering-grade materials smoothly with fewer clogs.

10. Anycubic Kobra S1 Combo Multicolor

A high-speed, enclosed 3D printer with multi-color capability, AI camera monitoring, and auto calibration—ideal for advanced users seeking precision and versatility.

Each of these enclosed 3D printers fits a different purpose — from hobbyist setups to pro-grade manufacturing. When you pick one, consider build volume, filament compatibility, bed/print temperature, enclosure insulation and filter/ventilation features.

How to Optimize Your Enclosed 3D Prints

Owning an enclosed 3D printer gives you a major head start—but to truly unlock its potential, it’s all about smart setup and consistent habits. Here are some simple yet powerful ways to get cleaner, more reliable prints every time.

Start by placing your printer in a stable, low-draft zone. Even with an enclosure, external airflow can still pull heat away and cause temperature fluctuations. Stability also matters—vibration from nearby machines or tables can subtly affect layer precision.

Before tackling longer projects, pre-heat the build chamber (if your model supports it). This warms up the enclosure evenly and helps prevent warping, especially with large or high-temperature materials like ABS or nylon.

Next, focus on air quality and maintenance:

- Monitor ventilation or filtration. Even though the enclosure traps most fumes, you should still make sure your workspace has good air circulation or a built-in filter system.

- Maintain your print bed. Keep it clean and level to ensure proper adhesion. In an enclosed environment, heat retention can mask adhesion problems until it’s too late.

When dialing in print settings, remember:

- Match your filament profiles. Enclosures help tougher materials (ABS, PETG, nylon) perform well, but temperature, cooling, and fan speeds still matter.

- Use proper lighting or a viewing window. Monitoring progress without opening the chamber prevents thermal shock and keeps your print consistent.

Also, keep your firmware and software up to date. Many enclosed printers feature auto-levelling, live calibration, or remote monitoring tools—updates often improve these systems’ accuracy and safety.

If you’re printing creative or decorative projects—like ambient lights and fixtures similar to those in 3D Printed Lamps—plan your post-processing workflow early. A smoother, enclosed print reduces sanding, painting, or assembly time later.

Finally, treat every print as an experiment. Document what works and what doesn’t. Each filament, print speed, and chamber condition can change results slightly. Logging those details helps you fine-tune future prints and achieve professional-grade consistency.

Conclusion

Switching to an enclosed 3D printer is a smart move for any serious enthusiast. You’ll gain stability, safety, cleaner prints and the freedom to explore a wider range of materials. Whether you’re printing functional prototypes, decorative items or simply tinkering for fun, the ten models above give you excellent options for every budget. Take your time choosing the right one, and apply the best practices I listed to maximise results. Ready to step up your printing? Your next project is waiting.

FAQs

Q1: What makes an enclosed 3D printer different from an open-frame one?

An enclosed printer has a sealed or semi-sealed build chamber that keeps out drafts and helps regulate temperature. Open-frame printers leave the build area exposed, which can make prints more susceptible to warping and environmental issues.

Q2: Can I still use PLA filament in an enclosed printer?

Yes. PLA works well in enclosed printers, though the main advantage of the enclosure appears when using more demanding filaments (ABS, nylon, carbon-fiber blends) that require stable environments.

Q3: Are there any downsides to an enclosed printer?

One potential downside: more heat retention may require better ventilation or cooling control, especially for extended prints. Also, access for maintenance might be slightly more involved when printers are enclosed. But overall the benefits outweigh these minor trade-offs.

Q4: How important is ventilation or filtration in enclosed printers?

It’s crucial to note that certain filaments can release VOCs and ultrafine particles during printing. Enclosures help contain them, but having good ventilation or a built-in filter adds safety, especially if you run prints frequently or in shared spaces.

Q5: What should I look for when buying an enclosed printer?

Check build volume, compatibility with various materials, chamber temperature (if heated), enclosure insulation or structural integrity, filament sensor/auto-levelling features, filter or ventilation options, ease of maintenance, and support from the manufacturer or community.