Top 10 3D Printer Build Plate

In the rapidly evolving world of 3D printing, the build plate is a crucial component that can significantly influence the quality and success of your prints. Whether you’re a hobbyist or a professional, selecting the right build plate can make a substantial difference in your printing experience. Here, we explore the top 10 3D printer build plate, discussing their features, advantages, and what makes them stand out in the bustling market.

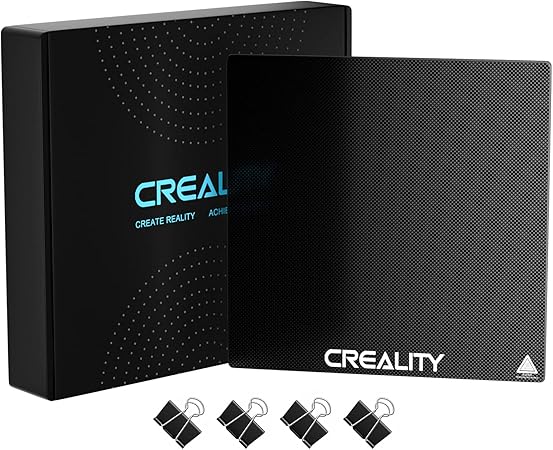

1. Glass Build Plate

Glass build plates are favored for their superb adhesion and smooth finish. They provide a consistently flat surface, ensuring your prints come out even and well-formed. One standout feature of glass plates is their resistance to warping; your prints will stay true to form from start to finish. They are also remarkably easy to clean—a quick wipe with isopropyl alcohol does the job. This type of build plate is perfect for those who value precision and a flawless finish.

2. Aluminum Build Plate

Aluminum build plates are known for their durability and excellent heat conductivity, which helps in rapid and even heating across the surface. They are particularly useful for printing materials that require high temperatures. Their sturdiness ensures they can withstand the test of time and extensive use. Aluminum plates are also fairly easy to maintain, making them a great choice for both beginners and experienced printers who need a reliable workhorse.

3. PEI-Coated Build Plate

PEI (polyetherimide) coated plates are a game changer when it comes to adhesion. Say goodbye to prints that warp or detach mid-print. The PEI surface grips the material firmly during printing and releases it gently once cooled. This feature is especially beneficial when working with tricky filaments like ABS or TPU. Moreover, PEI-coated plates reduce the need for additional adhesives, such as glue or tape, streamlining the printing process.

4. Magnetic Build Plate

Magnetic build plates are a revolutionary addition to the 3D printing world, offering the ultimate convenience of removing prints. Once your print is complete, you can simply remove the entire plate and flex it, popping the print off effortlessly. This is particularly handy for delicate prints that might be damaged by scrapers or other tools. Magnetic plates also make it easy to switch between different plates, allowing for continuous printing with minimal downtime.

5. Anodized Aluminum Plate

Anodized aluminum build plates combine the heat conductivity of aluminum with the added benefit of corrosion resistance. This type of plate is ideal for use in humid environments or when working with materials that emit corrosive fumes. Anodization also enhances the hardness of the surface, making it less prone to scratches, thereby extending the lifespan of both the plate and your prints.

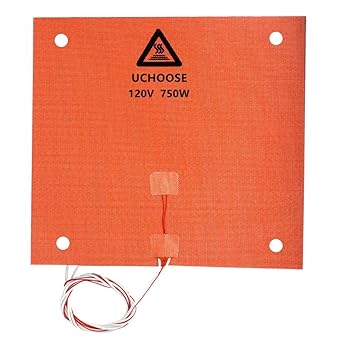

6. Silicone Heated Bed

Silicone heated beds are praised for their outstanding heat distribution. They help maintain a constant temperature throughout the printing process, which is vital for materials that are sensitive to temperature fluctuations. These beds are also lightweight and flexible, which can be advantageous in printers that have mobile build plates. Plus, their installation is generally straightforward, which helps in upgrading your setup with ease. You might want to check out our guide on 3D scanners too.

7. Borosilicate Glass Plate

Borosilicate glass is another excellent option for those who prefer glass build plates but need additional thermal stability. This type of glass resists thermal shock, meaning it can handle sudden temperature changes without cracking. It’s perfect for high-temperature prints and for users who frequently change the types of materials they work with.

8. Resin 3D Printer Flex Building Plate

Resin 3D printers are known for their ability to produce highly detailed and smooth prints, making them a favorite in industries such as jewelry making, dental, and model designing. However, one common challenge with resin printing is the post-printing process, especially when it comes to removing the finished object from the build plate without damaging it. This is where the Resin 3D Printer Flex Building Plate comes into play.

9. Carbon Silicon Crystal Bed

For those at the cutting edge of 3D printing technology, carbon-silicon crystal beds offer superior performance. These beds heat up incredibly fast and maintain stable temperatures, which can significantly decrease the time it takes to start a print. Additionally, their ultra-smooth surface ensures that the bottom of your prints is mirror-smooth, adding to the professional quality of the output.

10. Stainless Steel Build Plate

The stainless steel 3D printer build plate is the epitome of strength and durability. They are virtually indestructible, making them an ideal choice for heavy-duty printing. While they may require additional surface treatment for better adhesion, their robustness makes them suitable for high-volume or industrial printing environments where the plate needs to endure repeated use.

Final Thoughts

Each of these build plates has its own set of benefits that can cater to different printing needs and preferences. Whether you prioritize ease of removal, surface finish, durability, or thermal stability, there is a 3D printer build plate out there that will fit your 3D printing endeavors perfectly. Choose wisely based on your material needs and printer compatibility, and elevate your 3D printing experience to new heights!