3D Printer Nozzle Cleaners: Top Picks for Smooth Prints

A clogged 3D printer nozzle could lead to low print quality, skip layers, or worse, your project comes to a halt. It’s really frustrating to encounter this problem. To avoid this, you should consider using 3D printer nozzle cleaners. They help smooth extrusion, extend your printer’s life, and save you from wasted filament. This guide covers the best nozzle cleaners for home users and hobbyists. Great if you’re printing daily or just getting started.

Why Nozzle Cleaning Matters for 3D Printing

A clogged or partially blocked nozzle can cause under-extrusion, stringing, or complete print failure. Regular cleaning is key to:

- Preventing jams before they happen

- Maintaining consistent extrusion

- Extending the lifespan of your printer’s hotend

Recent studies have introduced innovative solutions to improve 3D printer maintenance and prevent common extrusion issues. One such development is an intelligent rapid nozzle cleaning control system that uses high-temperature melting and thermal analysis to clear blockages efficiently without damaging printer components.

Complementing this, another study presents a vibration-based nozzle cleaning system, designed to monitor printer performance in real-time and proactively prevent clogs. These advancements highlight the growing importance of automated and predictive cleaning methods in ensuring consistent, high-quality 3D printing.

Types of 3D Printer Nozzle Cleaners

Before jumping into product recommendations, here’s what you need to know about different types of cleaners:

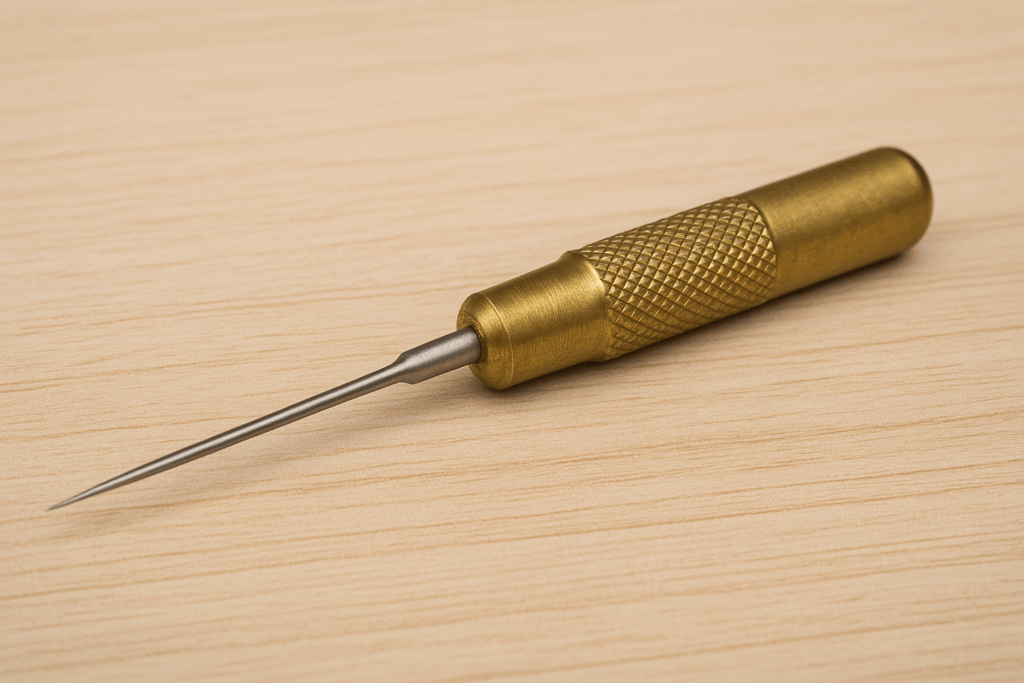

Needle or Pin Cleaners

These are thin metal rods designed to poke out blockages. Great for quick fixes but be gentle—they can bend or damage softer nozzles.

Nylon Cleaning Filament

Used like regular filament, this melts and scrubs out leftover gunk inside the hotend. It’s safe, efficient, and ideal for preventive cleaning.

Ultrasonic Cleaners

More advanced, but perfect if you frequently switch filaments or use filled materials. These devices use high-frequency waves to remove grime from removed nozzles.

Brass Wire Brushes

Not used inside the nozzle, but helpful for cleaning the exterior and heat block.

Building a full maintenance kit? Check out our essential 3D printer accessories for tools that pair well with these cleaners.

Top 5 3D Printer Nozzle Cleaners

Here are the best-rated nozzle cleaners you can grab right now, all chosen for reliability, ease of use, and user feedback.

1. 3D Printer Nozzle Cleaning Needles Kit (0.4mm)

✔ Includes 10 stainless steel needles

✔ Fits most 0.4mm nozzles

✔ Great for regular cleaning and quick fixes

Simple and budget-friendly—perfect for daily maintenance.

2. JAYO 3D Printer Cleaning Needles Kit

✔ Comes with compact case

✔ Flexible and rust-resistant

✔ Works with PLA, ABS, and PETG

Easy to store, even easier to use between prints.

3. FENGWANGLI Nozzle Cleaning Kit with Tweezers

✔ 10 needles + tweezers included

✔ Helps remove stubborn filament residue

✔ Compatible with various printer brands

Great for those who need extra grip and reach.

4. Creality Nozzle Cleaning Kit with Piercing Tool

✔ Designed for Creality hotends

✔ Includes needle and nozzle wrench

✔ Handy for deep cleaning or nozzle changes

A solid pick for Creality users needing full cleaning control.

5. Complete 26-Piece 3D Printer Nozzle Maintenance Kit

✔ Includes needles, brushes, tweezers, and wrench

✔ Works with multiple nozzle sizes

✔ Organized in a portable case

A great all-in-one option for hobbyists who want a ready-to-go toolkit for cleaning and minor repairs.

When Should You Clean Your Nozzle?

There’s no set rule, but you should inspect and clean your nozzle every 5–10 prints or when you notice:

- Uneven layers

- Clicking or skipping sounds from the extruder

- Under-extrusion or empty moves during printing

Even premium filament leaves micro-debris or absorbs moisture. Over time, that builds up. Preventive cleaning keeps things running smoothly and saves you time troubleshooting later.

How to Use Cleaning Filament (Quick Guide)

Using cleaning filament is simple and safe for most FDM printers. Here’s how:

- Heat the hotend to around 200°C (or the filament’s working temp).

- Unload the current filament.

- Insert cleaning filament and let it extrude a few centimeters.

- Retract the filament, then repeat steps 3 and 4 twice.

- Load your new filament and start printing.

Tip: Cut a fresh tip on the cleaning filament before inserting it each time. A sharp end grips leftover material better.

External Build-Up? Use a Brush

While internal clogs are more serious, don’t overlook external gunk. Burnt-on bits of filament can affect airflow and cause inconsistent heating.

Use a brass wire brush gently around the nozzle and heat block to remove charred plastic. Just be careful if your setup includes aluminum parts.

For stubborn exterior buildup, you might also consider soaking the removed nozzle in an ultrasonic cleaner.

Clean Nozzles = Clean Prints

A clean nozzle equals better flow. Better flow means stronger adhesion, more detailed features, and fewer print errors. Still dealing with stringing or blobs even after cleaning? It might be time to check out our 3D printer troubleshooting guide for deeper fixes.

Conclusion

Don’t let a tiny nozzle ruin your masterpiece. With the right 3D printer nozzle cleaner, you can avoid print failures and keep your projects running smoothly. Whether you prefer needles, filament, or ultrasonic baths, regular cleaning is the secret to better prints and less frustration. And if you’re planning to showcase your 3D prints at a seasonal gathering, check out our creative summer party decor ideas to add a fun, personalized touch to your display.

FAQs

1. Can I clean a 3D printer nozzle with a needle while it’s hot?

Yes, but be extremely cautious. Use gloves and avoid forcing the needle. Always heat the nozzle to extrusion temperature first.

2. How often should I use cleaning filament?

Every 5–10 prints, or whenever you change filament types. Especially important when switching from PLA to ABS or PETG.

3. Will cleaning my nozzle improve print quality?

Definitely. A clean nozzle ensures even extrusion, which improves layer adhesion, detailing, and overall finish.

4. Can ultrasonic cleaners damage my nozzle?

Not if used properly. Always remove PTFE tubing and clean only metal parts.

5. Are brass brushes safe for all nozzles?

Yes—for steel and brass nozzles. But avoid using them too hard on aluminum parts, as they can scratch or wear them down.